Controller-Level USB Configuration for Environments Where Behavior Must Be Defined at Production

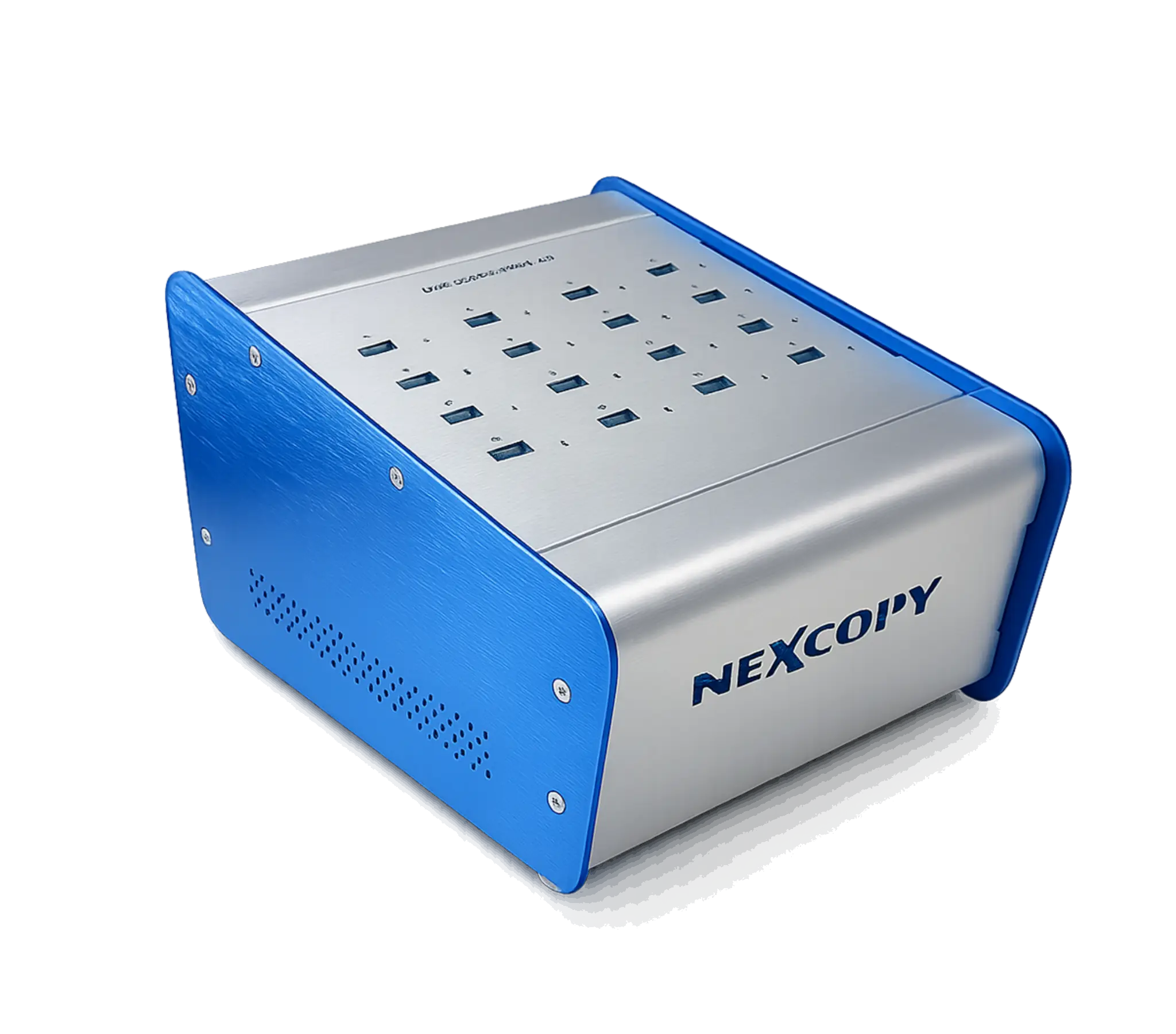

The USB160PRO is an advanced USB duplication system designed for organizations that must control how a USB flash drive behaves, not just what data it contains. It operates at the USB controller level, where device behavior is defined during production rather than managed afterward by operating system policies.

This platform is built for environments where operating system–based copying is insufficient. When requirements include hardware-enforced write protection, CD-ROM emulation, serial number control, or certified controller usage, configuration must occur independently of the file system. The USB160PRO provides that level of control.

The USB160PRO is used when consistency, validation, and repeatability are mandatory. Each USB device produced behaves as intended because its configuration is written directly to the controller rather than applied afterward by software or policies that can be altered or bypassed.

When the USB160PRO Is the Right Choice

The USB160PRO is PC-based by design. It connects to a Windows workstation to provide visibility and control during device setup and production. This approach is chosen when flexibility and configurability matter more than simplicity or push-button operation.

Organizations select the USB160PRO when USB behavior must be defined at production time, when device settings must be verifiable, and when post-production modification is not acceptable. In contrast, standalone duplicators prioritize speed and ease of use but trade away fine-grained configuration options available only through a PC-connected workflow.

If a project requires defining how a USB device presents itself to an operating system — including partition layout, read-only enforcement, or descriptor values — the USB160PRO is the appropriate platform.

Why the USB160PRO Uses a PC-Based Architecture

The USB160PRO relies on a PC-connected workflow because advanced USB controller configuration requires access to vendor-specific commands that cannot be issued by standalone duplicators.

USB flash controllers are programmed using proprietary command sets defined by the controller manufacturer. These commands are required to configure low-level functions such as hardware-enforced write protection, CD-ROM emulation, fixed disk behavior, descriptor values, and controller-resident metadata.

Standalone duplicators operate using generic mass-storage protocols, which prevents access to these vendor-specific controller commands. As a result, they cannot define device behavior during production.

The USB160PRO uses a Windows-based workflow to provide the visibility, validation, and command-level access required to configure USB devices correctly and consistently.

Controller-Level USB Configuration

The USB160PRO configures USB flash drives at the hardware controller level rather than relying on operating system–based file copying. This approach ensures device behavior is permanently defined during production.

Hardware-Enforced USB Write Protection

One of the primary use cases for the USB160PRO is hardware-enforced USB write protection. Write protection is written directly to the USB controller rather than applied through software, operating system policies, or file system permissions.

Once configured as read-only, data cannot be added, modified, or removed. This protection persists across all operating systems because it resides in the controller.

Drive Manager PRO Software

At the core of the Pro Series is Drive Manager PRO software. It provides a controlled interface for configuring flash drives with advanced controller-level features.

Using Drive Manager PRO, USB devices can be configured with CD-ROM emulation, multi-LUN layouts, and partition behavior written directly to the controller.

The Pro Series also supports writing USB serial numbers and descriptor values such as VID and PID, defining how the device enumerates on any host system.

Who This Product Is For

- IT departments producing controlled USB media

- Medical device manufacturers distributing regulated data

- Defense contractors requiring immutable storage

- Software vendors distributing licensed content

- Training organizations delivering certified materials

Key Specifications

- 16-target USB duplication system

- USB 3.0 connectivity (backward compatible)

- Windows-based production workflow

- Supports controller-level write protection, CD-ROM emulation, and multi-LUN configuration

- CE, FCC, and RoHS certified

- For full engineering specifications and supported behaviors, view the USB160PRO Technical Datasheet

Video Overview

A demonstration video is available showing hardware-enforced USB write protection in operation. The demonstration illustrates how write protection persists across systems and environments because enforcement occurs at the controller level.

USB Write Protection – How It Works

Defining USB Behavior at Production

The USB160PRO is Nexcopy’s flagship platform for environments where USB behavior must be defined during production rather than managed after deployment. Organizations using the USB160PRO typically have strict requirements around data immutability, device identity, and long-term consistency across distributed systems.

Nexcopy works with customers to confirm controller-level requirements, validate production workflows, and ensure the USB160PRO is configured correctly for regulatory, security, or operational objectives before rollout.