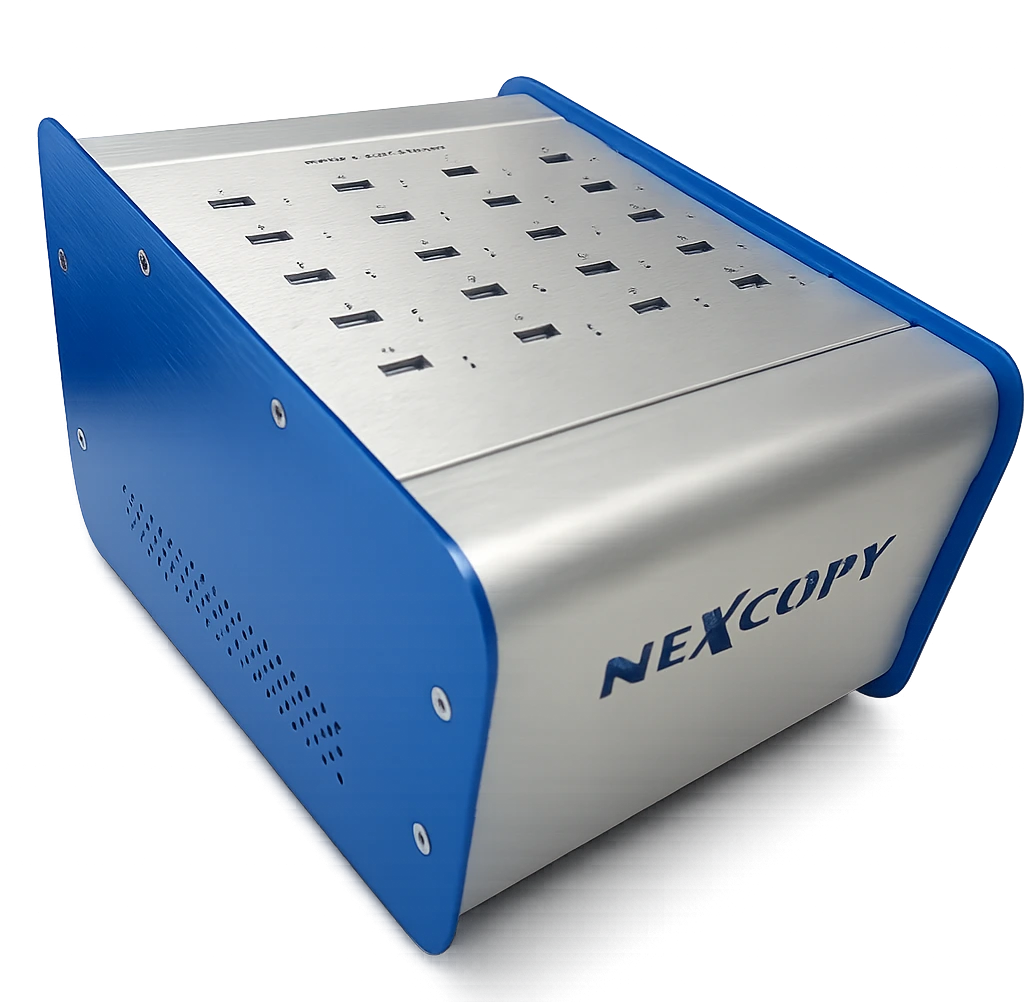

The Original Pro Series Platform That Defined Controller-Level USB Configuration

The USB200PRO represents the original flagship platform that established Nexcopy’s Pro Series architecture. First introduced in 2008, the USB200PRO was designed for organizations that required long-term reliability, controller-level configuration, and predictable device behavior during production rather than relying on operating system controls after deployment.

Unlike general-purpose duplication systems, the USB200PRO was built around the principle that USB devices should be configured intentionally at the time of manufacture. When requirements include hardware-enforced write protection, CD-ROM emulation, fixed disk behavior, serial number control, or strict controller qualification, configuration must occur below the file system at the controller layer.

The continued use of USB200PRO systems in production environments reflects Nexcopy’s long-term approach to product support and lifecycle stability. Many customers deployed this platform over a decade ago and continue to operate it today, demonstrating the durability of both the hardware and the underlying architecture.

When the USB200PRO Is the Right Choice

The USB200PRO is selected when organizations require proven controller-level control and prefer a mature, stable platform that has been deployed in real-world environments for many years.

It is commonly used in environments where consistency across production batches matters more than adopting the latest interface standard, and where long-term repeatability and post-sale continuity are important considerations.

Projects that involve defining how a USB device presents itself to an operating system — including read-only enforcement, partition layout, or descriptor values — are well suited to the USB200PRO architecture.

Why the USB200PRO Uses a PC-Based Architecture

The USB200PRO relies on a PC-connected workflow because advanced controller-level configuration requires direct access to vendor-specific command sets. These commands cannot be issued by standalone duplicators operating through generic mass-storage abstractions.

USB controllers are programmed using proprietary command sequences defined by each controller manufacturer. These commands are necessary to configure functions such as hardware-enforced write protection, CD-ROM emulation, fixed disk behavior, descriptor metadata, and controller-resident attributes. A full Windows environment provides the level of access required to issue and validate these operations correctly.

Standalone duplicators prioritize simplicity and speed, but they do so by abstracting the USB command layer. As a result, they cannot perform the controller-level sequencing required for advanced configuration.

The USB200PRO’s architecture was intentionally designed to favor visibility, validation, and precise control over device configuration rather than hiding complexity behind simplified automation.

Controller-Level USB Configuration

The USB200PRO configures USB flash drives at the controller level rather than relying on file-system-based duplication. This allows device behavior to be defined during production and ensures that those characteristics remain consistent after deployment.

Hardware-Enforced USB Write Protection

A primary capability of the USB200PRO is true hardware-enforced write protection. With this platform, write protection is written directly to the controller rather than applied through software controls, operating system policies, or file system permissions.

Once configured as read-only, data cannot be added, modified, or removed from the device because enforcement resides within the controller itself. This behavior is independent of the host computer, operating system, or security configuration.

Write protection follows the device wherever it is used. The protection state persists until intentionally modified using Nexcopy tools during a controlled production process.

Drive Manager PRO Software

The USB200PRO is operated using Drive Manager PRO software, which provides the interface required to configure flash drives at the controller level. The software was designed to support deliberate, repeatable configuration rather than simple push-button duplication.

Using Drive Manager PRO, devices can be configured with CD-ROM emulation, disk partitioning, and other controller-resident behaviors. These attributes are written directly to the controller and are not dependent on how an operating system interprets the device.

The platform also supports writing USB serial numbers and descriptor fields such as Vendor ID (VID) and Product ID (PID), allowing devices to present themselves predictably across systems and environments.

Copy Methods and Production Workflows

The USB200PRO provides multiple production copy methods to accommodate different operational requirements. Rather than forcing all workflows through a single master-source model, the system supports flexible sourcing and content preparation.

Six Copy Methods Supported

- File Copy – copy files and folders only

- Full Device Copy – bit-for-bit duplication

- Smart Device Copy – intelligent copy excluding empty sectors

- IMG Copy – write from pre-built image file

- Copy Add – append files to existing content

- Unique Data Streaming – individualized data per device

Unique Data Streaming for Individualized USB Content

Unique Data Streaming allows different data to be written to each USB device during a single job. This capability is used when content must be individualized, such as license files, certificates, identifiers, or device-specific assets.

Data preparation is intentionally flexible. Organizations can integrate this feature into their own internal pipelines rather than being forced into a rigid structure dictated by the system.

This approach supports automation while still allowing teams to control how data maps to each device during production.

USB Data Extraction to Host Storage

The USB200PRO also supports read-back workflows, allowing data to be extracted from connected USB devices to host storage. This is commonly used in inspection, collection, validation, or archival scenarios.

Extracted data can be consolidated into a single destination or automatically separated by source device. Optional post-processing actions such as secure erase or formatting can be applied after extraction to support controlled reuse.

Key Specifications

- Includes all features of the USB200PC, in addition:

- 20-target USB duplication system

- USB 2.0 architecture

- Create multi LUN partitions at the controller level

- Create USB CD-ROM partitions at the controller level

- Hardware based write protection (media is read-only)

- Control descriptor field settings such as VID, PID, SCSI, Product IDs

- For full engineering specifications and system characteristics, view the USB200PRO Technical Datasheet

For an overview of Nexcopy’s current USB duplication platforms, visit our USB duplicator solutions page.

Evaluating USB200PRO Versus Current-Generation USB160PRO?

Organizations comparing the legacy USB200PRO platform with Nexcopy’s current-generation USB160PRO often want to understand differences in controller support, production workflows, long-term availability, and qualification impact. Both platforms serve professional environments, but they are designed for different lifecycle stages and operational priorities.

Nexcopy can assist with platform comparison, migration considerations, qualification continuity, and availability planning to help determine whether maintaining an existing USB200PRO deployment or transitioning to USB160PRO is the right path for your organization.